The Constituent Parts of the Metal Circular Saw Machine

The Main Constituent Parts of the Metal Circular Saw Machine are Control Panel, Discharging Device, Servo Feeding System, Hydraulic Clamping, Oil Mist System, Servo Motor, Automatic Lubrication System, Scraps Discharge Machine, Storage type Automatic Rack and so on.

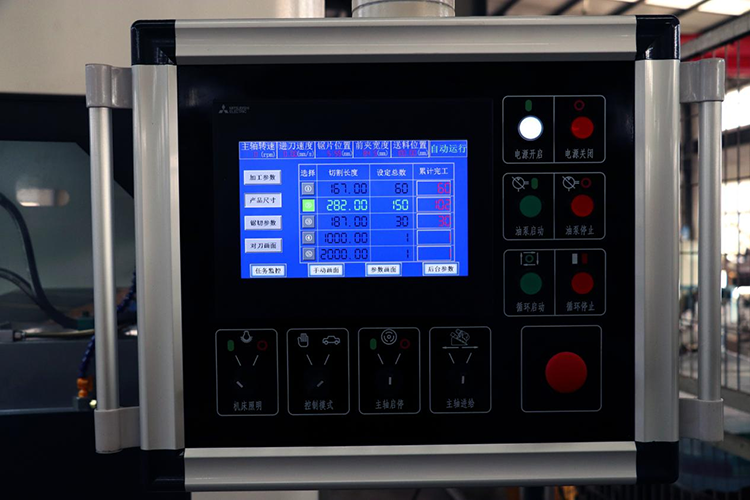

1. Control Panel

Convenient operation,the system adopts automatic control of Japan Mitsubishi PLC system Use touch screen to input cutting operation parameters.

2. Discharging Device

Convenient material collection and processing,realize the separation of finished product and material head.

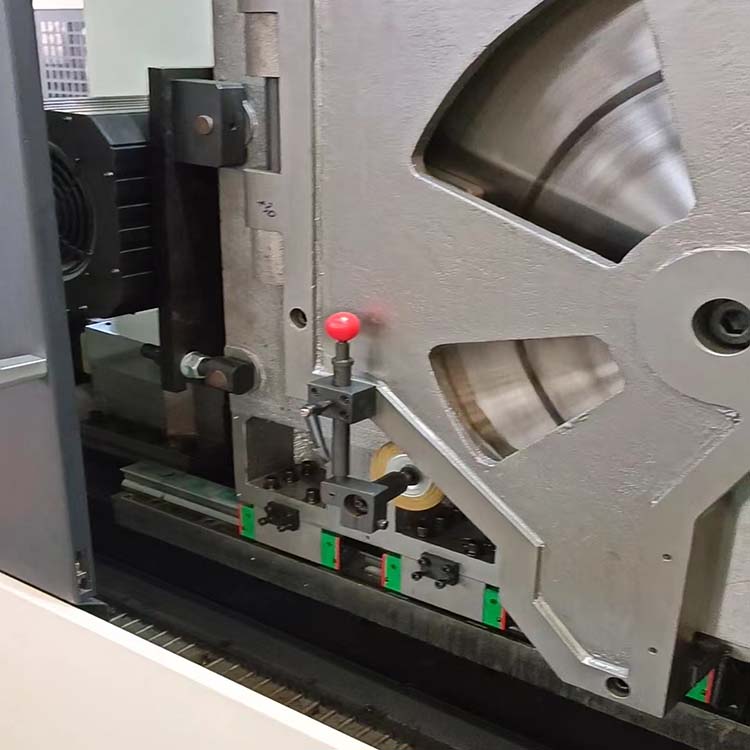

3. Servo Feeding System

It adopts Servo motor and high-precision ball screw for feeding,linear guide,overall yaw feeding,stable and fast feeding.

4.Hydraulic Clamping

Adopt hydraulic rail clamping to ensure the stability of cutting bars and tubes during cutting.

5. Oil Mist System

The oil mist system can quickly increase the saw blade and cutting speed, and improve the quality of the product.

6.Servo Motor

Servo motors are used for spindle feed and power, which can be quickly started to make the machine run smoothly.

7. Automatic Lubrication System

Automatic lubricating system for the whole movement of the whole machine, Setting as per request, Keep machine running best condition.

8. Straight and Level Feeding

Integrated slide horizontal feeding mechanism, ball screw with linear feed, cutting stability high precision, prolong the life of the saw blade.

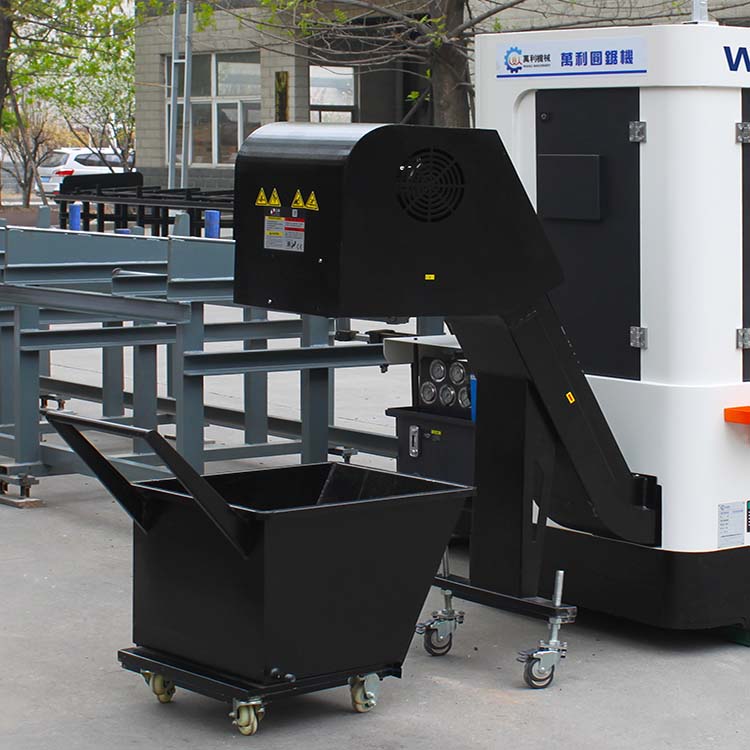

9. Scraps Discharge Machine

It is used for collecting all kinds of metal chips and nonmetal chips made by machine, Convey the saw chips to the collecting tool.

10. Feeding Frame: Storage Type Automatic Rack

Automatic hydraulic lifting material feeder to be arranged, waiting, to ensure selection mechanism of automatic, unmanned arrangement.